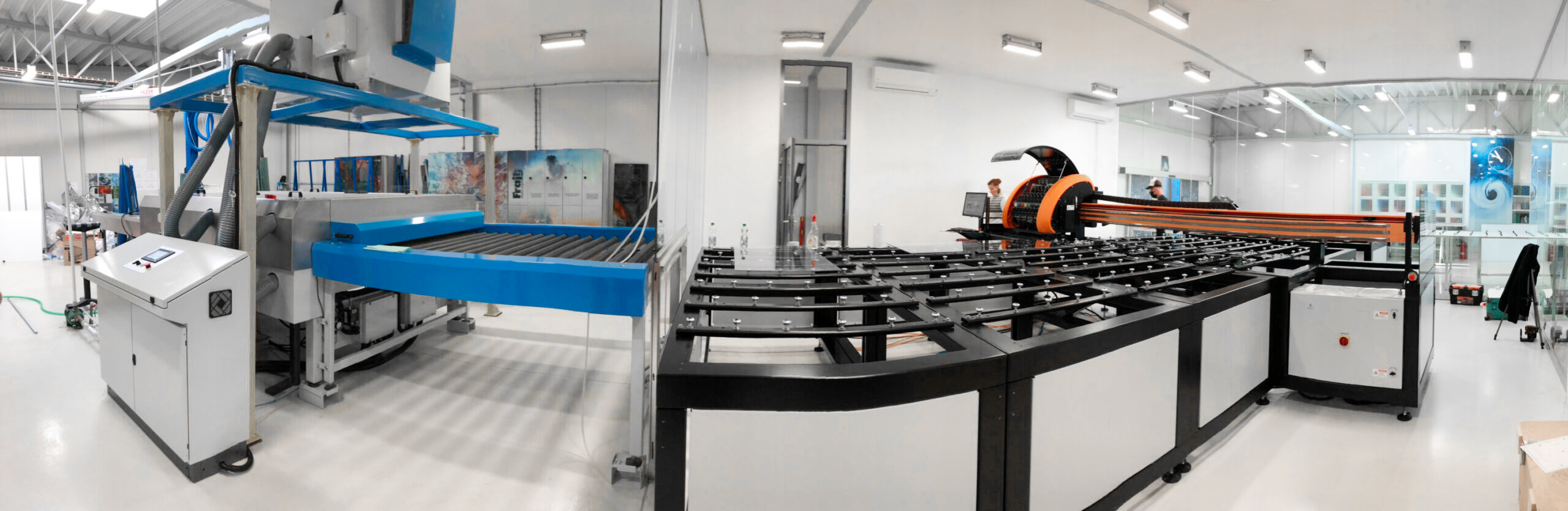

Ceramic ink printing on glass resists UV radiation, weathering and physical damage.

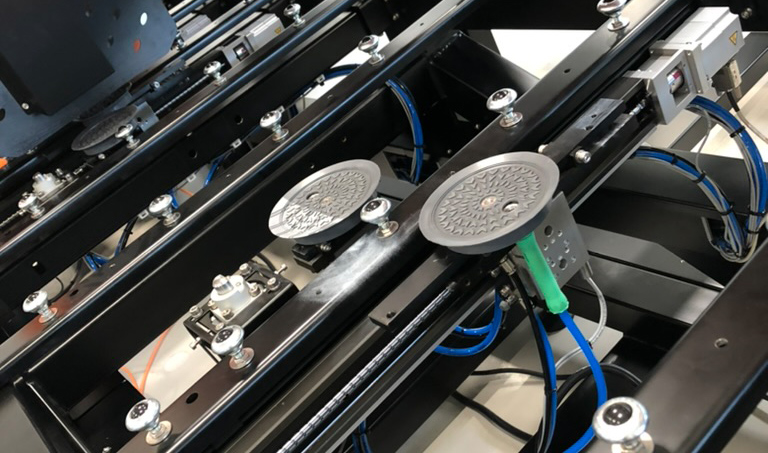

It is designed for exterior and interior use. The IMAGE GLASS production line consists of cutting and shaping , an automatic washer, a glass ceramic printer, a hardening furnace and a laminating furnace. Together with glass processing and finishing operations, it is a closed production process.